San Guillermo Micro Hydroelectric Power Plant

Since 2002, SIEyE SRL has developed generation projects with renewable energy sources. These projects are the following:

This Micro Power Plant started as an investigation project for its conception, design, construction and sustainable hydro-energetic use. It was evaluated and approved by specialists appointed by the Argentine Technological Fund (FONTAR), within the CAEFIPP (Concurso Público para la adjudicación de Créditos a Empresas para el Financiamiento de Proyectos de Desarrollo Tecnológico: Public Tender for the Issuance of Credits to Companies for the Finance of Technological Development Projects), within the framework of the Contrato de Préstamo suscripto (Registered Loan Contract) with the Inter-American Development Bank (IDB); which issued its “No Objection”.

As from the existing work in the San Guillermo Diversion Dam, in the locality of Barreal, Province de San Juan, a new hydro-energetic structure has been projected. This work is located between the spillway and the union zone with the canal that conducts the flow supplied by the areas that we called “fuses”.

Among the structures built it’s worth mentioning a waterproof canal section of approximately thirty-five (35) meters. This section includes the bars fences and lockgates required for the project. This canal is typically called Feeding Canal. Its section is almost constant; nevertheless altimetrically and planimetrically, its depth and width varies; and it finishes in the engine room, where it has approximately 2.70 meters of length in metallic structure.

The purpose of these bars fences is to avoid that branches, sleeves and other objects affect or alter the flow in the turbine rotor. The purpose of the lockgates is to interrupt the flow of water to the Feeding Chamber, and consequently to the turbines. It is required to do annual maintenance jobs, which must be carried out without the presence of water. Due to this fact, these mechanic structures are required. They not only prevent water from coming in, but they are also useful in case of an inconvenient.

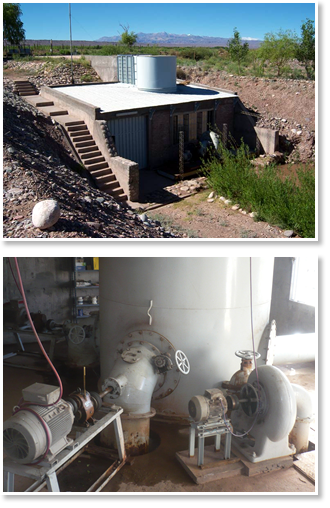

The feeding chamber is a structure composed by a metallic cylindrical structure of 2.60 mts. of diameter and 6.00 meters of height where four Francis de pozo turbines run.

The turbine of this installation is the Francis de pozo type, which flow is regulated by the blades in the distributor, according to the availability of water. The maximum flow estimated for calculations, required by each turbine, is about 500 liters/sec.

The opening and closing mechanisms of the blades in the distributor are manual and are placed next to the admission of each turbine. The maximum power has been estimated for a maximum opening and a waterfall of approximately 5.00 meters.

The rotor axle transmits its rotation to an increase gear train, and from this element to the generator, converting kinetic energy to electric energy.